The high-pressure (HP) oil system that used for the fuel injection system on the Ford 6.0L engines can be very tricky and time consuming to diagnose when problems arise. It is important to have an understanding on how the system works to be able to accurately diagnose and repair it. Here is a little background on this system before we begin.

Let’s start with a description of the components in the high-pressure oil system.

- High-Pressure Oil Pump (HPOP) – This is a cam gear driven pump that is supplied with oil from a reservoir on the top of the engine block. The reservoir, which is shared with the OEM oil cooler, is used to keep a constant supply of oil available for the HP oil system. Oil is picked up from the oil pan and sent from the low-pressure oil pump to the oil cooler, through the oil filter and into the HP oil reservoir. From there the oil is fed to the HPOP, pressurized, and sent to the oil rails and fuel injectors. This pump is responsible for providing the volume of oil required for each injection cycle. There are two different styles of HPOP. The early trucks (03-04) used an aluminum bodied swash plate style pump that fails often. The late trucks (05-and up) used a cast iron v4 configured pump. This late style pump has very few problems. The main issue that is seen with the late pumps is the Snap-to-Connect fitting (STC) coming apart and causing a leak. Normally, after replacing the STC fitting with the updated part, the pump will continue to work without issue.

- Injection Control Pressure Sensor (ICP) - This 3-wire variable capacitance sensor uses a 5-volt reference signal that supplies the PCM with a voltage reading that indicates system pressure. It is primarily used to provide a feedback signal to the PCM for use in IPR valve modulation. The ICP sensor signal is also used by the FICM to command the fuel injection timing.

- Injection Pressure Regulator Valve (IPR) - This valve is what controls the pressure in the HP oil system. This is a normally open valve that is duty cycle controlled by the PCM. The valve works by closing to create a restriction to the oil drain path. As the valve closes, the restriction increases and the pressure in the HP oil system is increased.

- J-Tube or STC fitting – This part connects the HPOP to the Branch Tube which supplies both sides of the engine with HP oil to fire the injectors.

- High-Pressure Oil Rails, Standpipes, and Dummy plugs – The Standpipes are used to provide a connection between the Branch Tube and High-Pressure oil rail. The HP oil rails are used as a manifold to supply each bank of injectors with HP oil. They also act as a reservoir for oil in the system. The HP oil rails come in two varieties. The early trucks have straight, round rails and the late trucks have large “wavy” rails. There are multiple differences between the two. The standpipes are different, early ones are threaded into the branch tube and use a quick disconnect style braided stainless steel line to connect to the oil rail. The late style standpipes are no longer threaded and consist of two sections. The upper section of the standpipe passes through the oil rail and seals it from leaks. The bottom section uses an o-ring seal where it connects to the branch tube.

- Branch Tube – The supply tube that feeds HP oil supply to each bank of injectors via the standpipes and HP oil rails.

- Fuel injectors – This is where the magic happens. The fuel injectors consist of two separate circuits, oil and fuel. The injectors use a spool valve that operates using a 48-volt signal and 20-amp pulse to open and close the valve at the top of the injector. The spool valve once opened allows the pressurized oil to enter the injector. The hydraulic force of the oil pressure is multiplied by 7.1 times using an intensifier piston to push the fuel out of the injector and into the combustion chamber. This can result in fuel pressure upwards of 28,000 psi.

- The HP oil system is contained internally inside the engine. If there is a leak in the system, it should not be visible externally. The most common instance of an external leak would apply to 2003 and early 2004 models where the ICP sensor is located on the HPOP cover. On those trucks it is possible for the oil to leak through the body of the sensor and would present itself as an external oil leak at the rear of the engine. Replacement of the ICP sensor would be the appropriate repair in that instance and usually it requires replacement of the wiring pigtail as well.

It is well known that this HP oil system can be quite problematic. Too often, problems associated with the high-pressure system are misdiagnosed, resulting in loss of time and money and the problem remains. If done properly, problems within this system can be figured out with a minimal amount of effort and hassle.

Here is a guide that our own techs use in the shop to diagnose the high-pressure system quickly, efficiently, and definitively.

Tools needed: Ford repair data, mechanical Oil pressure gauge, Scan tool or data monitor, telescoping mirror, selection of wrenches, rachets, sockets and extensions, IPR valve socket, ICP sensor socket, a known good IPR valve, shop towels

- Check for trouble codes and write them down. This will help aid in the diagnostic process.

- Duplicate the problem and verify that the crank no start is not being caused by something else.

- Check oil level and quality.

- Check base engine oil pressure. If the base engine oil pressure is lower than 12 psi, verify proper operation of the low-pressure system. If the pressure is 12 psi or above, continue to the next step.

- Use a data monitor/scan tool, during cranking to determine if a high-pressure oil leak may be the problem. If the base engine oil pressure is above 12 psi (with engine fully warmed up), the IPR duty cycle reaches 85% during cranking and ICP does not reach 500 – 600+ psi, the high-pressure oil system may be compromised. If a high-pressure oil leak is suspected, proceed to the next step.

- Disconnect ICP sensor (in passenger side valve cover on 2004.5 and newer, back of engine under turbo on 2003-2004.25) and try to start. If truck starts and runs with ICP disconnected, the ICP sensor and or wiring may be the problem. Replace and retest as necessary. If truck still won’t start and or run, proceed to step 7

- Remove IPR and inspect screen. If screen is blocked by debris, replace the screen, determine the source of the debris and take corrective action. If screen is damaged or missing, replace IPR. If problem persists, proceed to step 8

- Remove both valve covers. While cranking the engine, inspect for a GROSS oil leak from the top o-ring seal on each injector. (Note: The injector has a small oil port to exhaust the high-pressure oil once through the injector body so some leakage from that port on the injector is considered normal) A GROSS leak may be described as oil “shooting/spraying out from under the oil rail”. If no GROSS leak is observed, proceed to the next step.

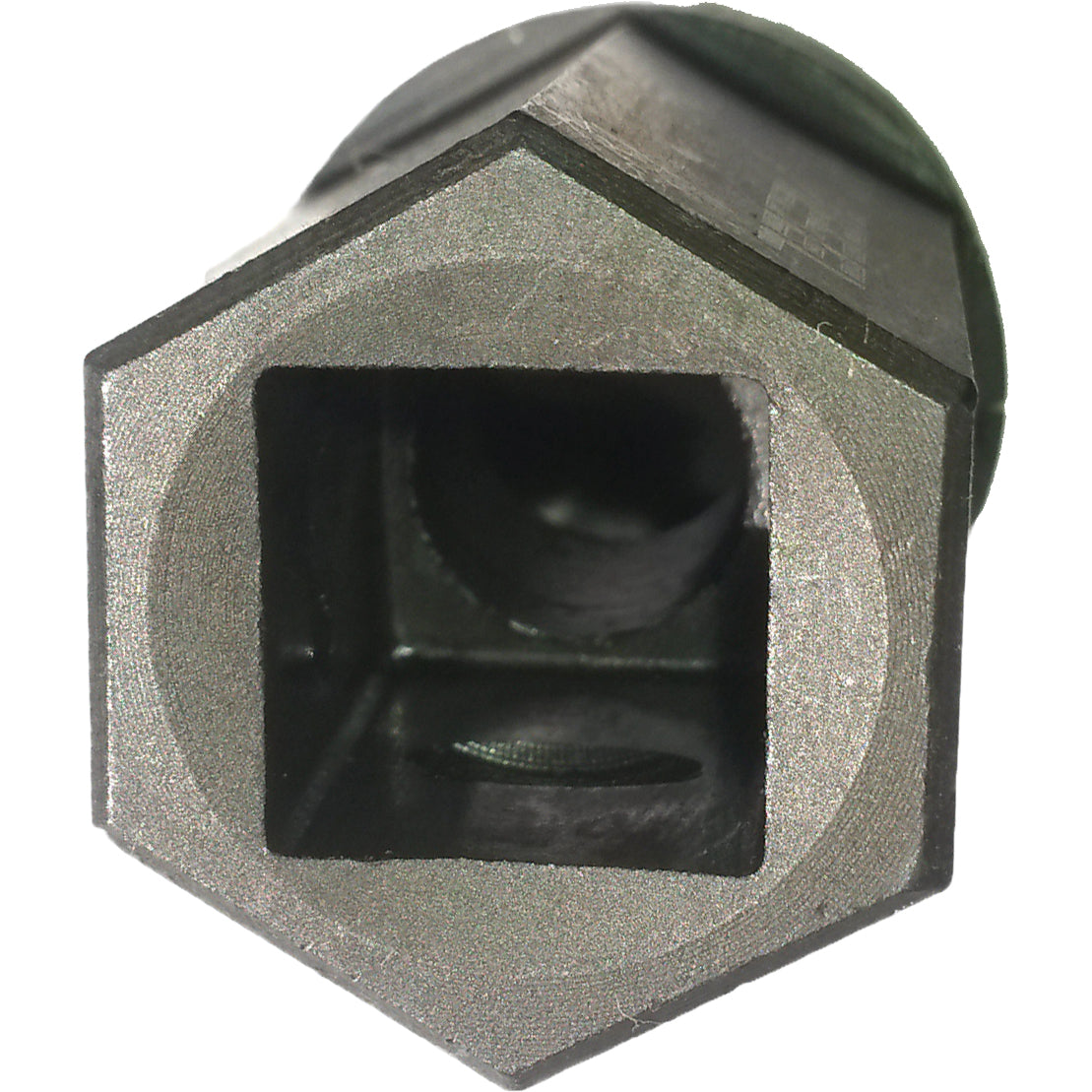

- If the truck is 2003 – 2004.25 and has round oil rails, inspect the under valve cover braided hose connections at both ends of each hose for GROSS leakage while trying to start the engine. If truck is 2004.5 and later with “wavy” oil rails, remove the standpipes and dummy plugs to inspect all o-rings. If braided hoses or standpipes and dummy plugs are ruled out, proceed to step 10. (Note: there are updated standpipes and dummy plugs with improved o-rings, identified by the wrench size that fits them. 1/2” Sq. drive or 10mm Allen = old style, 12mm Allen = Updated) If problems persist, proceed to the next step.

- Remove the HPOP cover. If truck the is a 2003 – 2004 with a round (swash plate style) pump, inspect ‘J’ tube connections at the pump and branch tube, if connections are intact and properly sealing, replace the high-pressure pump. If truck is 2005 or newer with a cast iron (piston style) pump, inspect STC fitting for damage or failure. If STC has failed (came apart), inspect carefully for damage where the branch tube may have contacted the back cover of the engine. In some instances, this impact during failure can fracture the rear cover causing a continuous external oil leak. If STC fitting is still intact, remove the HPOP and STC fitting and inspect for compromised o-ring seals under each. Correct o-ring seal issues and or replace the STC fitting and retest.

- If the truck still won’t start, replace the HPOP and retest.