Ford Powerstroke Problems Across Generations

Here’s some of the most common problems for each generation.

Ford 6.7 Powerstroke Problems (2011 - 2016)

After dealing with the problems of the Navistar-designed Powerstroke engines, Ford decided to develop the next Powerstroke in-house. Since this engine was built specifically for their trucks, the engineers were able to add new features that improved drivability and performance. This includes reverse flow heads, valves with individual pushrods, and an air-to-water intercooler. The result wasn’t just a better fit for heavy hauling and towing, it was also a major improvement in reliability. That said, there are still some common 6.7 Powerstroke problems you should watch out for.

EGR Cooler: The redesign moved the EGR cooler to a location that makes it easier and less costly to replace. This cooler design is a cartridge style as well, so when applicable the core or guts of the cooler can be changed, rather than the entire assembly. This cooler still has the failure characteristics of most other factory coolers, in regards to overall expansion and contraction of the metal parts.

Exhaust system issues: Exhaust gas temperature (EGT) sensors fail so frequently that Ford extended the warranty on this part. Extreme exhaust temperatures can cause the sensor to strip the exhaust bung during removal, requiring retapping or replacement. EGT sensors are used by the ECU to monitor the catalytic converter and diesel particulate filter.

Oil cooler: The cooler used in these engines is less fragile than those found in earlier Powerstrokes. However, a better oil cooler may still help with keeping oil temperatures under control.

Ford 6.4 Powerstroke Problems (2008 - 2010)

Early on, the 6.4l liter promised to address most of the problems with the 6.0l, while offering better overall performance. Tuners quickly found ways to increase power with just a few ECU programming changes, while commercial owners appreciated the stock engine's overall improvement in power and fuel economy.

While the 6.4l did address some of its predecessor’s problems, it also added new ones. These problems are compounded by the design of the truck. Many engine components can only be accessed by lifting the cab. This adds several hours of labor to repairs, making parts replacement far more costly on the 6.4l than other Powerstrokes. For this reason, addressing 6.4 Powerstroke problems by upgrading failure-prone components may result in larger cost savings over the vehicle’s life than any other model on this list.

Diesel particulate system: The particulate filter captures soot from the exhaust gas. Once the filter is full, the engine goes into regen mode, spraying diesel during the exhaust stroke to burn off this soot. During regen, power and fuel economy drops while exhaust temperatures increase. Over time, this filter can become permanently clogged, forcing the engine to stay in regen mode and eventually requiring replacement. This hampers performance and increases temperatures across the engine. The process also forces diesel into the crankcase. This dilutes the oil, which may make it less effective at lubricating the engine.

EGR cooler: To address the EGR cooler failures of the 6.0l, Navistar added a second cooler to spread out the thermal load. However, these coolers are still prone to cracking. Exhaust enters the horizontally-mounted cooler first, so it experiences more heat than the vertical cooler. As a result, the horizontal cooler tends to fail before the vertical cooler.

Oil cooler: Debris in the oil or coolant can clog the cooler, leading to increased oil temperatures. This cooler is buried under the intake manifold and turbo system, which means it is very difficult and costly to replace. We offer two ways to address this problem. Our remote cooler mounts below the brake booster, allowing you to flush or replace the oil cooler easily, once the kit is installed. We also offer a supplemental cooler, which adds more cooling capacity to the oil cooling system and improves the filtration system as well.

Water pump: The stock pump's plastic impeller has the same cracking issues as the one used in the 6.0l. Our replacement water pumps have a billet aluminum impeller that won’t crack.

Cooling system: The factory radiators tend to crack and separate where the plastic tanks meet the aluminum core.

Cylinder head: Like the 6.0l, the head bolts used on this engine may not provide enough clamping force to protect the head gasket. Upgrading to head studs should address this problem.

Ford 7.3L Powerstroke Problems (1994-1997)

While it may have the same displacement as the IDI engine used in earlier Ford trucks, this was a clean sheet design. This old school turbo diesel didn’t make much power, which arguably keeps everything understressed for a long service life. Depending on the engine version, the injectors only fire once or twice per cycle, so they experience less wear than modern injectors. It’s also missing the cooled EGR system and particulate filter of more modern diesels, eliminating two common points of failure.

In this case, older isn’t necessarily better. While it is reliable, this engine makes less than half the horsepower and torque of the newest Powerstroke offering.

Ford 6.0 Powerstroke Problems (2003-2007)

While the 7.3l was famously reliable, Ford and Navistar knew it wouldn’t be able to reach upcoming NOx emissions requirements. Even if it could, the new common rail diesels being used by their competitors were beating Ford in performance. Their answer was an all-new engine using the latest technology.

The 6.0l Powerstroke offered far more horsepower and torque than anything else on the market, making it the clear winner for towing rigs. A variable geometry turbo, four valve per cylinder heads, and a strong block with a reinforced bed plate promised excellent performance. Unfortunately, all that new technology brought a long list of problems.

EGR cooler: While EGR cooler failures are common across a wide range of diesel engines, these failures are more frequent on this Powerstroke. The undersized cooler has trouble dealing with exhaust heat, which may lead to faster metal fatigue and soot buildup. Also, because the engine coolant had to flow through the engine oil cooler before making its way to the egr cooler, a restricted engine oil cooler could be a factor in egr cooler failure.

Oil cooler: The 6.0l uses a water-to-oil cooler buried under the intake manifold and turbo systems. The cooler’s small passages can clog easily, which can lead to increased oil temperatures and a restriction of coolant flow to the EGR cooler. In some cases, the cooler may rupture, pushing pressurized engine oil into the coolant system. This type of failure can create serious cooling system problems and require replacement of all rubber components.

Water pump: The stock water pump uses a plastic impeller. A combination of age and repeated heat cycling can make this plastic brittle. Cracks in the blades reduce coolant flow, which may lead to overheating. We offer a replacement pump that solves this problem by using a billet aluminum impeller.

Cylinder heads and head bolts: Head gasket failures are a common problem on these engines. Often, failures can be traced to the head bolts, which don’t provide sufficient clamping force. Making the switch to stronger studs allows for increased clamping loads, helping the gaskets stay in one piece. These cylinder heads are also known for cracking, which normally can be resolved at a machine shop with the capability to repair cracks and replace valve seats.

Cooling system: The factory radiators used an aluminum core with plastic tanks. Over time, the radiator can separate at the seams where these parts meet. We offer all-aluminum radiators that shouldn’t have this separating problem.

Ford 6.7L Powerstroke Problems (2017 - 2019)

While the 6.7l carried over for the 2017 model year, the Ford Super Duty was completely redesigned. This meant the powerplant had to be repackaged to fit in the new engine bay. Ford's designers took advantage of this opportunity to improve intake and exhaust flow, increasing torque.

Since this is still a relatively new engine, we don’t have a clear picture of the common failures this engine will have. However, the EGR cooler still has the same restrictive passages as Ford’s previous coolers, and oil temperature may be an issue with heavy towing. We offer high performance EGR coolers and oil coolers to help address these problems.

Ford 6.7L Powerstroke Problems (2020-Today)

The third generation of the 6.7l diesel builds upon its predecessor instead of replacing it. The biggest change is a switch from aluminum to steel pistons. These new pistons are shorter, making them almost the same weight as the old pistons while offering increased strength and reduced friction. Other changes, like a two piece intake manifold and a faster firing injection system, improve overall performance.

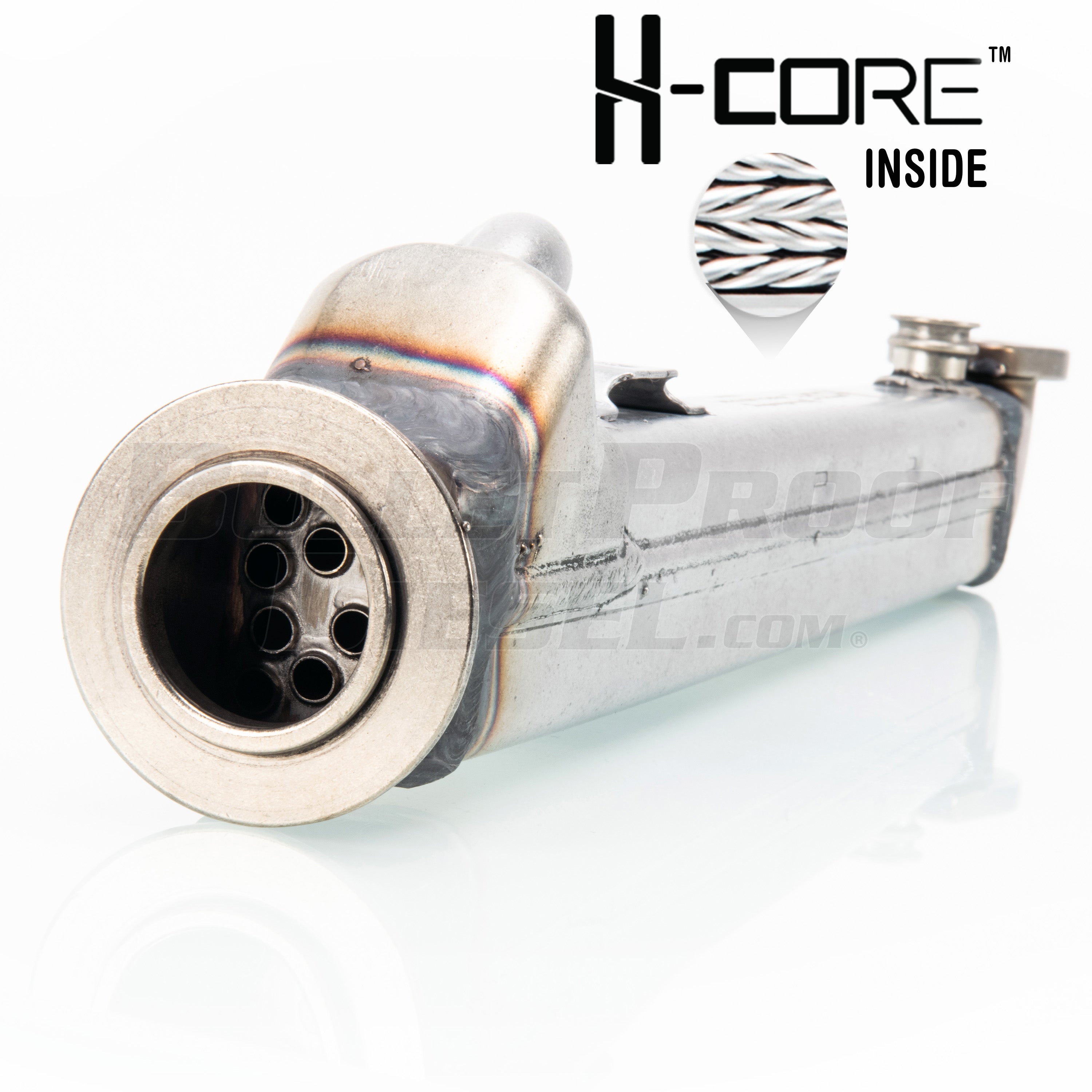

Like the previous Powerstroke, this engine is too new for us to know the most common points of failure. That said, this engine’s EGR cooler doesn’t address the common failure points of Ford’s other EGR coolers. That’s why we already have an H-Core EGR cooler available for this engine.

Ford 3.0L Ford Powerstroke Problems (2018 -2019)

Initially sold only on top trim models, this F-150 diesel engine was quietly dropped just two years after introduction. Although it’s based on the Lion engine used by Jaguar and Land Rover, there are enough changes to this engine to make it difficult to know it’s weak points.

*Some models/specific variants will still be available in the 2021.

Ford Powerstroke Problems in General

EGR coolers: Factory EGR coolers can fail in several ways, plugging and/or rupturing are the most common. Most factory EGR Coolers use thin, rectangular passages that may clog with soot over time, restricting exhaust gas flow. While it is possible to remove and clean the cooler, the rate of carbon build-up can vary widely between engines and vehicle use. This makes it hard to create a preventative maintenance schedule that effectively stops blockages.

Heat cycling flexes and contracts the cooler. Over time, this may cause the case to crack. It’s not uncommon for failures to occur in extreme conditions, such as pulling a heavy trailer up a steep hill. The added heat from the engine can be just enough to cause failure in fatigued metal components.

When an EGR cooler fails, coolant and exhaust gases can mix. If exhaust enters the coolant system, the added pressure may be enough to push the coolant out of the radiator cap valve and into the overflow tank. As the cooling system drains, the engine may overheat. If coolant enters the exhaust stream, it may enter the engine via the EGR system. A slow leak may drain the cooling system over time. Large leaks could lead to problems inside the engine. Since liquid doesn’t compress, a large amount of coolant can take up space in the combustion chamber, effectively increasing cylinder pressure. In severe cases, this may cause hydrolocking and internal engine damage.

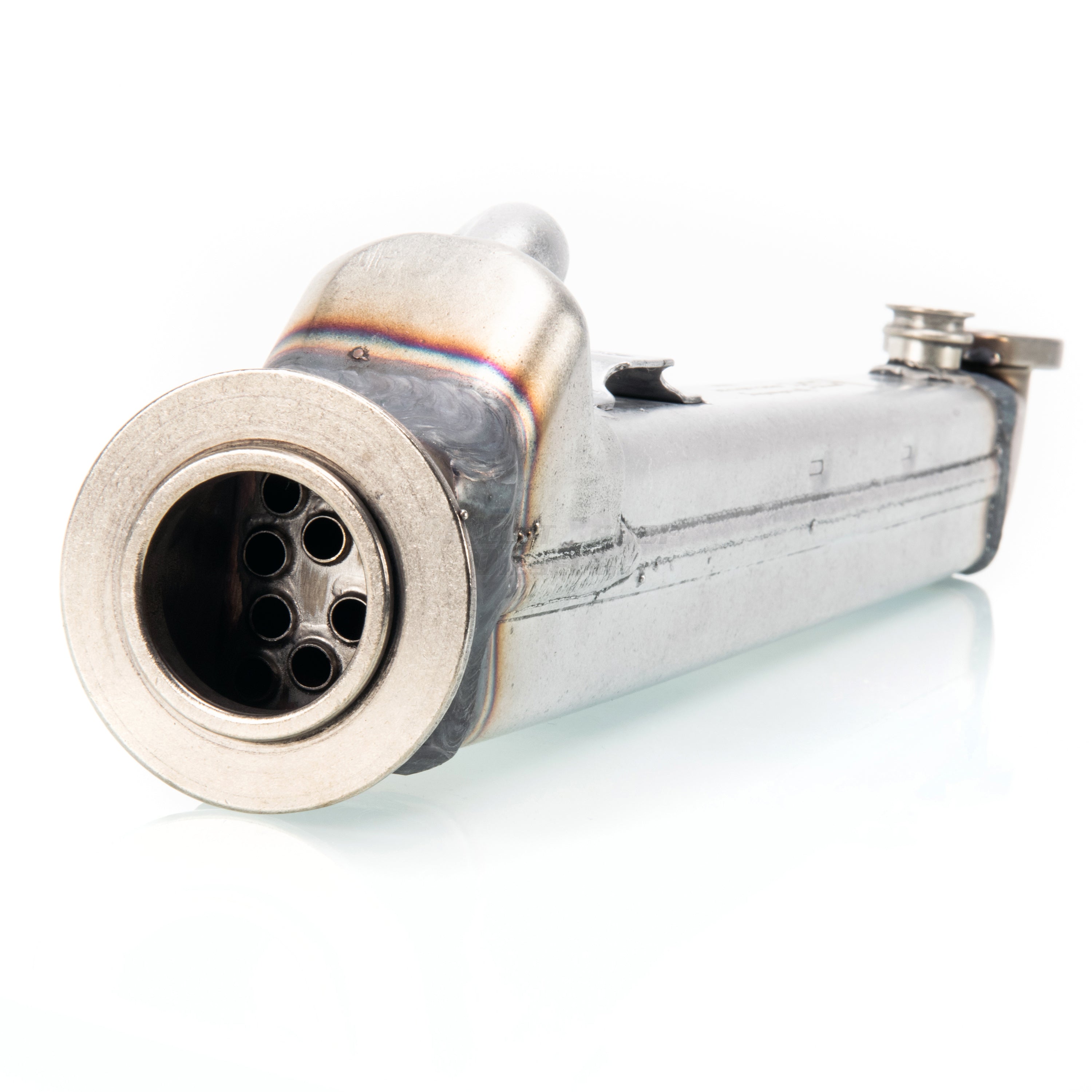

Our EGR coolers address the faults in the stock coolers. They’re built using stainless steel and have stronger bulkheads that can withstand heat cycles. On the inside, you’ll find large diameter tubes which allow exhaust gas to flow through the inside of the tube.. This could help reduce the chance of soot clogs. They’re arranged in a patented helical design that handles flexing from heat cycles better than straight tubes, even further reducing the chance of fractures.

Oil Cooler: Most Powerstroke diesels use a water-to-oil cooler mounted directly to the block. While coolers used in some of these engines are prone to failure, either by plugging up or rupturing, there are other options. Upgrading to a more effective cooler or even an air-to-oil cooler, could help to keep oil temperatures under control, protecting the engine.

What about your Powerstroke diesel?

This content was written by a 3rd party and updates/corrections will be updated over time.