Motor oil doesn’t just keep parts lubricated; it also helps keep your engine cool. As it flows through the cylinder head, engine block, and the piston cooling ports, oil absorbs heat, transferring it across the engine block. In most engines, the transfer of heat between the oil, block, and coolant is enough to keep temperatures under control.

Some engines, like the 6.0 Power Stroke, take this a step further by adding a cooler to extract heat directly from the oil. While the 6.0’s oil cooler is effective, it also has a history of pattern failures. These problems can be addressed by installing a 6.0 oil cooler relocation kit or a complete 6.0 Power Stroke oil cooler upgrade.

Common Problems with the Stock Power Stroke Oil Cooler

The 6.0l Power Stroke uses an oil-to-water cooler. Oil and coolant pass through a series of small channels inside the oil cooler. This transfers heat from the oil to the coolant. From there, the coolant releases heat through the radiator. While this is effective, the design is known for frequent failures that may put your engine at risk of overheating and mechanical problems.

The passages inside the oil cooler are tiny. While this increases their surface area for better heat transfer, it also makes these passages easier to clog. Contaminants in the cooling system from corrosion, additives, and gasket material can work their way to the cooler, which may seal up passages over time. It is possible for dirt, soot, and sludge to cause similar blockages on the oil side of the cooler.

The oil cooler sits in the valley of the engine, where it is exposed to massive amounts of heat. This can reduce cooling efficiency and increase thermal stress on the cooling block. In some cases, extreme heat and stress may lead to splits in the fluid passages, allowing the oil and coolant to mix. This creates a sticky emulsion that can create a real disaster inside of the cooling system.

The oil cooler retains a protective screen, that helps to filter the oil being diverted to the high-pressure oil pump (HPOP). There’s a good chance that this HPOP filter screen will fail as it ages and could lead to oil pump failure. The oil supplied to the HPOP, is then converted into high pressure oil, which is used to drive the fuel injectors. Even if the pump is still working, debris passing through a broken filter could find its way into the injectors and cause all sorts of problems.

Symptoms of a Failing Oil Cooler

If the oil cooler is working effectively, the oil temperature and coolant temperature should be about the same. Oil temperatures more than 15 degrees warmer than the coolant temperature, during unloaded (not towing), highway speeds, may indicate a failing or restricted oil cooler. Over time, increased oil temperatures may lead to premature failure of mechanical components, particularly in high-stress situations, like climbing hills or towing near the vehicle’s payload limit.

After passing through the oil cooler, the engine coolant is directed to the EGR cooler. If the movement of coolant is restricted inside of the oil cooler, it may lead to overheating and eventual failure of the EGR cooler. This type of EGR cooler failure can allow engine to enter into the engine cylinders causing overheating and cylinder head/head gasket failures.

How Do I Fix My Powerstroke’s Oil Cooler Problems?

Bullet Proof Diesel offers several solutions that address the pattern failures of the stock oil cooler. Installing a 6.0 oil cooler relocation kit moves the cooler out and away from the engine, making it easy to replace if it fails in the future. This remote location also allows you the ability to backflush the cooler periodically to help prolong its life. Another option completely eliminates the factory 6.0 oil-to-water cooler and upgrades it to an oil-to-air cooler. In this case a large air-to-oil cooler will be mounted in behind the air conditioning condenser and heavy duty oil hoses carry the oil to and from the engine.

What’s the Difference Between Oil-to-Water and Oil-to-Air Coolers?

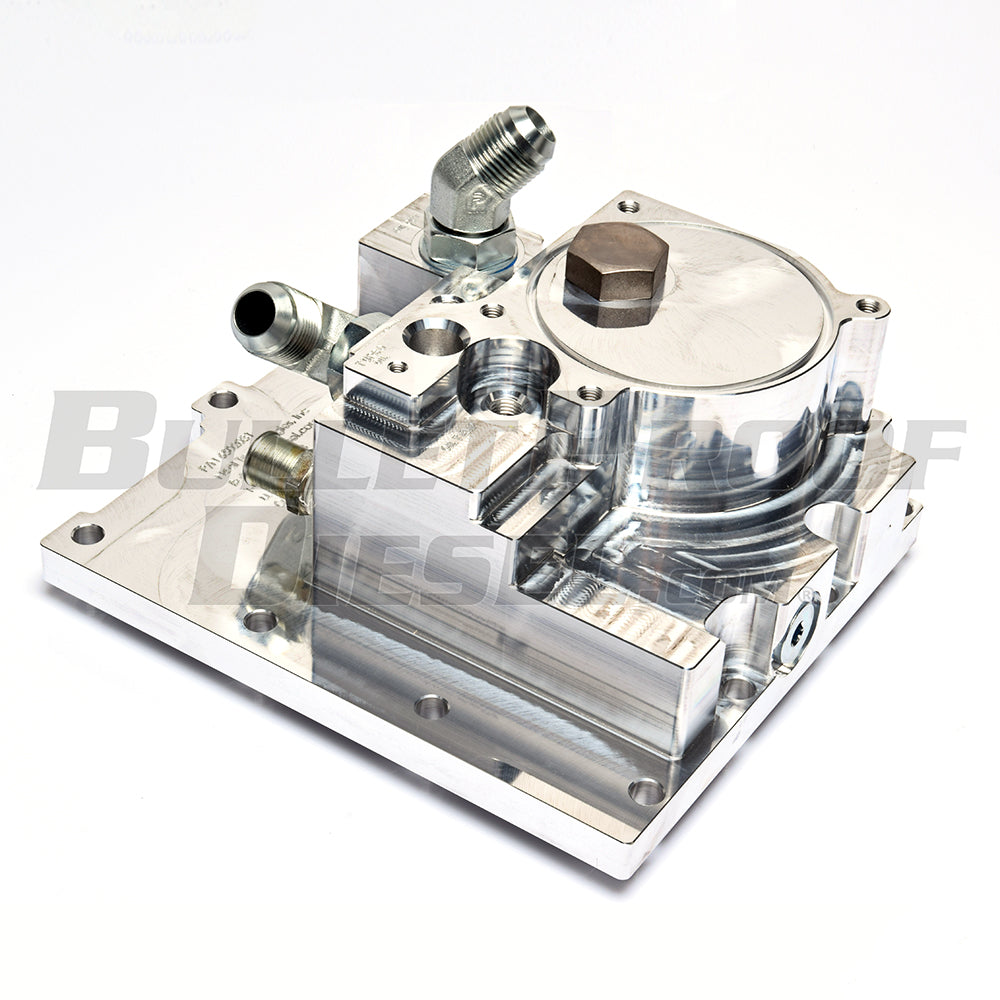

Our oil cooler relocation kit moves the stock cooler out of the engine valley. This keeps the stock oil-to-water cooling setup. The cooler mounts to a bracket that attaches in the engine compartment next to the passenger side battery. To make room, the kit includes a replacement vacuum reservoir that replaces the large OEM unit. Hoses transfer oil and coolant between the cooler and a fluid transfer block that mounts in the stock cooler location. Once this relocation kit is installed, the cooler can be accessed without removing the intake manifold and turbocharger.

Our 6.0 Power Stroke remote oil cooler kits replace the stock oil-to-water cooler with an oil-to-air cooler. This cools the oil directly using a large radiator, eliminating engine coolant from the oil system entirely. That means there should be no way for coolant and oil to mix at this point in the engine.

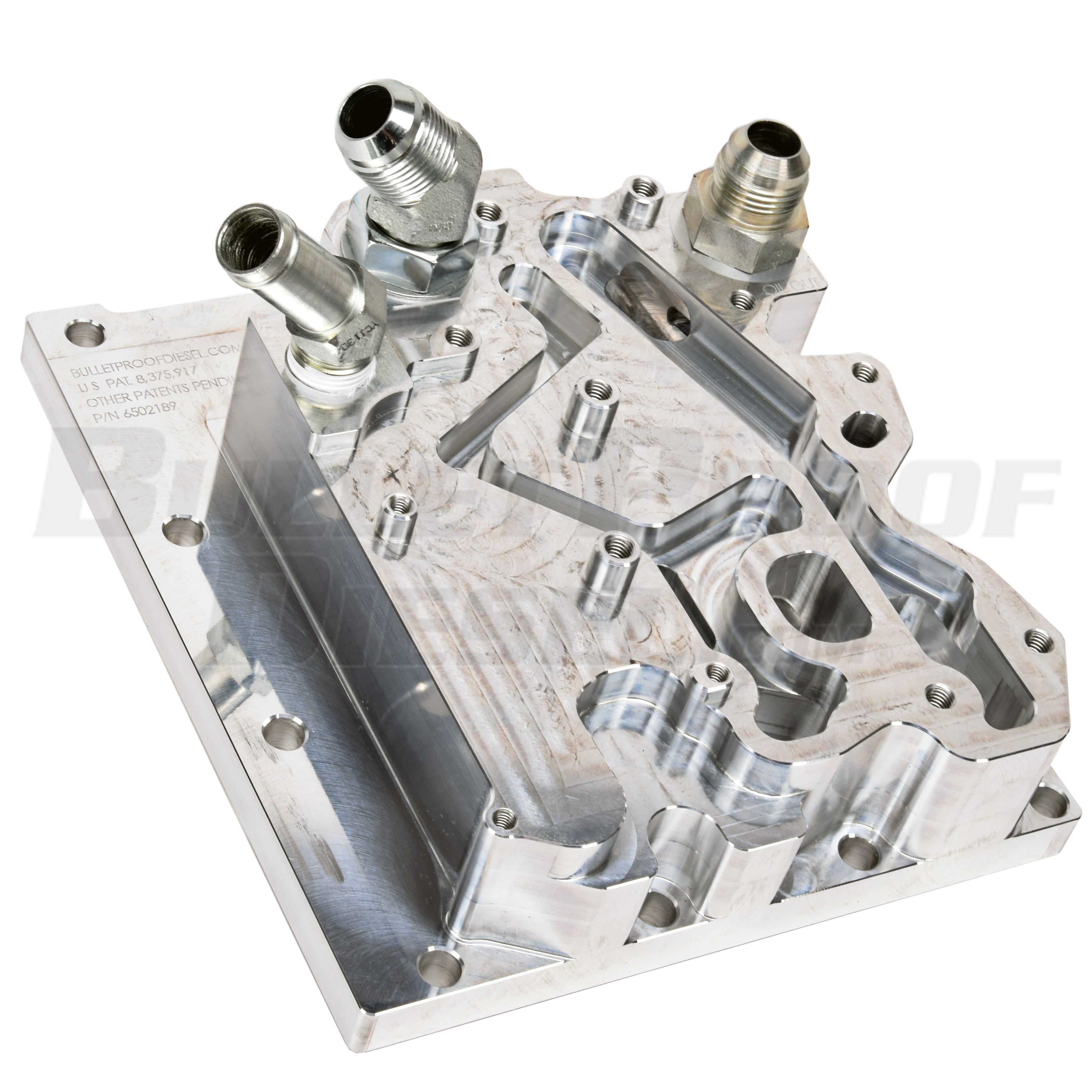

An oil transfer block replaces the oil-to-water cooling block. This meets up with the original oil passages, sending oil through a hose to the included radiator. This oil cooling radiator is mounted behind the air conditioning condenser. A return line sends the cooled oil back to the transfer block, where it is filtered before going into the HPOP.

Installing a relocation kit is a bit easier than installing an oil-to-air cooling kit. The oil-to-air kit requires the removal of the air conditioner condenser. If you want to do this upgrade yourself, you will need to have your A/C system drained of coolant before installation.

The transfer blocks on the relocation kit and upgrade kit both have an integrated heavy duty stainless steel HPOP screen, replacing the failure-prone stock screen. Oil-to-air cooler kits are available with an oil filter relocation kit. This replaces the engine’s cartridge filter with a larger, easier to access spin on style filter that mounts in behind the bumper on the drivers side of the truck.

What’s the Difference Between a Hot Climate Cooler and an All Climate Cooler?

Our hot climate coolers circulate oil through the cooling system 100% of the time for the best performance at high ambient temperatures, or heavy towing applications. Our all climate coolers have an included thermostat that allows some oil to bypass the air-to-oil cooler, until the engine oil is warm. This helps the engine warm-up and oil temperature regulation in the extreme cold climates. If you are not sure which one you will need, give their sales team a call and they will help you make the right decision.

What Do I Need to Install One of These Kits?

Most of the parts you will need are included with these installation kits. However, there are a few extra parts and modifications you may need, depending on the stock components used to build your truck.

- A special bracket kit is needed for 03-07 trucks that have had the factory original air conditioner condenser replaced. Most replacement condensers, whether they’re OEM or aftermarket, use a different designed frame surrounding the condenser, this difference is why the special bracket kit is necessary.

- 06-07 trucks moved the power steering cooler from the bottom of the radiator support, in behind the front bumper, to up high behind the air conditioning condenser. This high mounted location is directly in the way of the new air-to-oil cooler. This power steering cooler needs to be relocated to the spot in behind the bumper, using our power steering cooler relocation kit.

- Some early 2003 engines use a thread-on turbo oil feed tube. This should be replaced with an O-ring fitting tube or the most updated feed tube from the dealership.

- Some trucks have a 17 inch transmission cooler, while others have a 14 inch cooler. If your truck has the larger cooler, it can be moved down using the brackets included with the kit, giving you space to install the oil cooler.

- If you’re installing an external oil filter and you live in an area where the roads are salted, you may want to cover the fittings with a rubberized undercoating to prevent corrosion. Undercoating spray should be available at your local parts store.

When You Want the Best Oil Cooler for 6.0 Power Stroke Engines, Go With Bullet Proof Diesel.

Whether you have a performance engine, or you want to reduce the chance of breakdowns in your hauling rig, you can rely on Bullet Proof Diesel oil cooler solutions. We make it easy to install a 6.0 Power Stroke oil cooler upgrade on your truck. You can order a kit and any accessories you need from us directly. We include easy-to-follow instructions, walking you through each step of the installation process. Do not want to deal with removing and installing major engine components? We have a network of preferred installers. These professionals have experience with our components, so you can be sure your BulletProof oil cooler or relocation kit will be installed correctly.

https://bulletproofdiesel.com/search?q=6.0+oil+cooler+relocation+kit