- Change the engine oil regularly and use good, quality oil.

If you want your turbocharger to last longer, regular oil changes with quality oil of the correct viscosity is your best bet. Think of it as the top-notch self-care routine your turbocharger needs. Now, if you're someone who tows a lot with your truck or if you're living in a harsh climate, you might need to swap out the oil even more frequently. We'd also recommend you invest in good synthetic oil. Why, you ask? Well, it's just better. It can handle higher temperatures and provides overall superior lubrication than the conventional stuff. Trust us, if you start skipping your turbo's oil changes, nasty stuff like oil oxidation and sludge buildup start to happen. This leads to wear and tear, and ultimately, failure. Remember, a lot of turbochargers depend on oil for both cooling and lubrication. Therefore, a clean and cool oil supply isn't just nice to have...it's essential for your turbo's happiness.

-

Warm up the engine before putting it under load and let the turbo cool down before shutting the engine off.

Just like you wouldn't jump into a tough workout without stretching first, it's always a smart move to allow your engine and turbocharger to warm up before getting down to business. This small act ensures the oil can freely move throughout the engine, giving all those integral moving parts good lubrication. You

see, when things are cold, the oil is a bit thicker and the tolerances inside the engine and turbocharger are just a smidge tighter causing hindrance in oil circulation and lubrication. So, going full throttle from cold is like skipping the warmup at the gym, it can lead to premature wear. You don't need to idle the engine forever, just take it easy for the first few miles until things heat up. Then, it's business as usual.

On the flip side, turbochargers can create a heap of heat, so shutting the engine off straight after a drive can cause the oil to overheat inside the center housing. This can eventually lead to premature wear of the bearings and possibly even complete failure over time. It's a good habit to allow your truck to cool down for at least 30 seconds to two minutes before shutting it off. This is especially important after towing or hard driving, and always avoid revving the rpm before shutting the engine off. Consider turbo timers; they let your engine idle and shut down on its own ensuring a safer cool down.

-

Service the air filter regularly.

A stuffy, dirty air filter can cause your turbocharger to lose its mojo and power. Imagine running a marathon while trying to breathe through a clogged nose. Not a great feeling, right? That's how your turbocharger feels with a dirty air filter.

Worse still, it could lead to abnormal airflow at the turbo inlet, causing oil seals to fail. Talk about a domino effect! Without a fresh air supply, your car's performance takes a nosedive. Now, here's the main role of air filters: they stop junk from sneaking into your turbo and engine. If the filter or its housing is damaged, it's like leaving your front door open at night - uninvited guests might just visit.

So, here's a pro tip: Give your air filter a check-up every time you change the oil. If it's looking gross or damaged, swap it out. Don't forget to check the housing where the filter lives too. Make sure it seals well when the filter is installed. If you spot any damage to the housing or the filter, it's best to fix it ASAP to avoid any potential problems.

- Try to keep the boost level down overall, less heavy use can extend the life.

Have you ever wondered about the relationship between boost pressure and the lifespan of your turbocharger? Well, it’s quite simple - the higher the boost pressure, the higher the rotational speed of the turbo. This speedier rotation can lead to quicker wear and tear, especially if your oil isn't well-maintained.

But don't worry, you can keep your turbocharger in tip-top shape with a few simple tricks. One of them is just taking it a bit easier when you're out on the road. Less strain on the turbocharger can help extend its lifespan. The same principle applies to the rest of your engine as well.

Keep in mind, your turbo isn't meant to constantly work at its peak range. Doing so could lead to early failure. It's like with anything else - too much stress and your turbo is more likely to fail prematurely. So remember, a little moderation can go a long way towards keeping your car running smoothly for longer!

- Make sure there are no leaks or restrictions in the exhaust or intake system.

Let's get real about boost leaks and exhaust leaks - they are the ultimate turbo killers in our beloved machines! Not only do these pesky air leaks rob your truck of its power and performance, they're also a downright menace to your turbocharger. If not detected and repaired in time, boost and exhaust leaks can cause an abnormal and dangerous increase in the exhaust temperature. If you're not careful and this gets overlooked, the temperature could soar high enough to inflict serious damage to your turbo and even worse, your engine.

I know it sounds bad, but there is hope! You have the power to stay ahead and manage unexpected situations that may arise by using your eyes and ears. By regularly inspecting the intake and exhaust system, you should catch potential problems before they rear their ugly head. The silicone boots that connect the turbo to the intercooler and the intercooler itself are common spots for boost leaks. The up pipes between the turbocharger and the exhaust manifolds are a common spot for exhaust leaks. Be alert and keep your ears open for unusual hissing or ticking sounds while you're on the go. These sounds are your first sign that something might be amiss. Another common symptom of air leaks - apart from a drop in power and performance - is thick, black smoke billowing from your tailpipe. Any time something seems off, you should have it checked out.

If you want to take an additional step towards preventing problems, why not arm yourself with an exhaust gas temperature gauge installed right at your exhaust manifold? This handy tool can be your knight in shining armor. It lets you keep an eye out for any rise in temperatures that may cause harm to your robust diesel-powered buddy. Remember this golden rule though - NEVER allow the exhaust temperature to cross the 1250°F threshold for more than a few quick moments. Ensure you stay vigilant about this to keep your turbocharger whirling and your engine purring like a king. So, care for your diesel vehicles and let them continue to power your journeys!

- Avoid lugging the engine.

Have you ever heard of 'Lugging the Engine'? It's not a dirty word, but it's a habit we need to shake.

Picture this: You're cruising on the highway, towing a hefty trailer. Your diesel beast is in 5th gear, humming along but...wait! You need to overtake. The temptation to rely on pure torque and power is there, but resist. Why? This is what we call lugging the engine.

Lugging happens when your engine labors under load at low RPMs. Sure, your diesel truck is a powerhouse, but lugging can mess up the balance of air and fuel in your engine and hike up your exhaust temperature. Worst-case scenario? Damage to your turbocharger or other engine parts. Not cool, right?

Now, lugging is more common with manual transmissions, but don't be fooled - automatics aren't immune! The trick to avoiding it is simple: downshift.

Your turbo system transforms even the smallest engines into torque titans, but don't let that fool you into a false sense of security. Whether climbing a steep hill, overtaking on the open road, or hitting the fast lane on the motorway, downshift into a lower gear. Your gears are performance partners - they help distribute the load and keep your diesel truck running smoothly.

Remember, a savvy combination of gear changes and turbo boost not only gives your truck that power punch, but it also limits the wear and tear on your turbo system. So, remember to downshift, diesel lovers. Make the most of your gear, keep that engine humming, and you'll be cruising carefree for miles to come!

- Use a quality fuel additive that increases the cetane level.

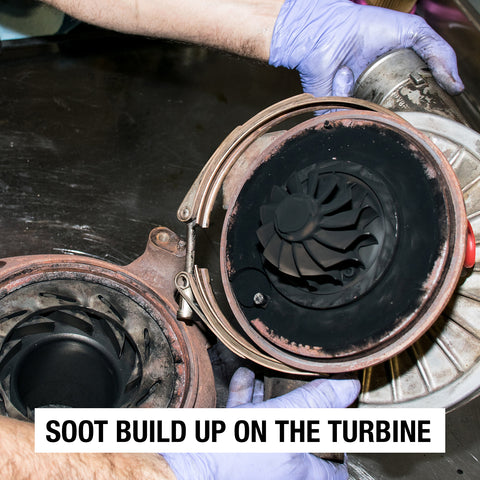

We all know soot and carbon deposits can be a real pain, especially for the gems of modern diesel engines: variable geometry turbos. It gets messy when these deposits stick around, causing your turbo to struggle and sometimes, even seize up. That's not what you want when you're cruising down the highway, right?

But here's the good news: there's a superhero in the diesel world known as the cetane booster. This magic ingredient in fuel additives can help you dodge the soot monster and keep your turbo's exhaust side squeaky clean.

The cetane booster is a kind of an ignition point shrinker. It makes your fuel ignite quicker and burn fuller which means fewer pesky particulates messing up your ride's performance. The result? Reduced chances for your turbo to stick and less smoke blowing out of your tailpipe.

So, if you’re after smooth acceleration and want to avoid the dreaded over boost condition and potential head gasket failures, consider giving these cetane boosters a try. Not only will they help you maintain your truck's power and performance, but they'll also keep the heart of your diesel, the VGT turbos, in top shape.

The road ahead is a lot clearer – and cleaner – with cetane boosters in your diesel fuel. So, let's keep those trucks rolling, shall we?

- Avoid long idle times and short trips.

Diesel trucks are real powerhouses - they're literally built to do heavy lifting. But just like any efficient machine, they're meant to operate under certain conditions to deliver their best performance. One of those conditions? Operating the engine regularly at normal temperatures.

You see, frequent short trips aren't a diesel engine's best friend. Neither are long idle times. If you're driving a diesel truck equipped with a Variable Geometry Turbocharger, aka a VGT, these conditions could be even more problematic.

Here's why: Short trips often don't allow the engine to reach its full operating temperature. Sounds harmless, right? Not quite. This could keep moisture in the oil, leading to premature turbo failure. Yes, your tough-as-nails turbo could wave the white flag sooner than it should, all because it's not reaching the right temperature. And it's not just about the turbo. Long-term internal engine problems could also creep up because of this.

In short, a stuck VGT is bad news. It can disrupt the harmony of your diesel truck's engine, messing with its longevity and performance. So, remember, avoid short trips and excessive idling, and let your diesel truck do what it was built to do - work hard at the right temperatures.

-

Cook off soot/carbon buildup with a spirited drive.

The occasional short trip or long idle time is not going to cause much of a problem but if you find yourself doing it more often, you can help clean things out but driving the truck a little harder than you normally would. Get the engine RPM up and get the turbo warmed up and worked out. Using the higher temperatures of the exhaust can help cook off soot deposits that accumulate on the VGT parts.

-

Check the turbocharger electrical system.

It's essential to remember that variable geometry turbos, with their brilliant functionality, rely heavily on a good electrical supply to the actuator for them to operate flawlessly. So, one shouldn't forget to always perform regular checks for any exposed wiring and any sort of broken connectors that might be present at the VGT actuator. These checks are simple and are of utmost importance.

Poor electrical connections, which might seem like a small issue, can lead to erratic and unpredictable turbo operation - a situation that's far from ideal when it comes to any turbo-based system. Furthermore, it might shock you to know that in some cases, poor electrical connectivity can cause the VGT portion of the turbo to stop working altogether!

This not only hampers the smooth operation of your turbo, but it can also limit the range of usable power. As such, maintaining good electrical connections is not just about the smooth running of the turbo, but it's also key to utilizing the turbo to its full potential. So, just as any good mechanic would tell you, it’s worth the time and effort to check and ensure the robustness of your turbo's electrical connections.